Vacuum Sealer vs. Modified Atmosphere Packaging: Which Is Better

Discover the differences between vacuum sealers and modified atmosphere packaging with Jiaolong. Learn which solution best preserves product freshness. Explore the advantages of vacuum sealers vs. modified atmosphere packaging here.

- What Is Vacuum Sealing? A Simple Explanation

- What Is Modified Atmosphere Packaging (MAP)?

- Key Differences Between Vacuum Sealing and Modified

- Atmosphere Packaging

- How Each Technology Works: Vacuum vs. Gas Flushing

- Shelf Life Extension: Which Method Performs Better?

- Cost Comparison: Equipment, Materials and Operational Expenses

- Efficiency and Maintenance: Which Technology Is Easier to Manage?

- Food Compatibility: Best Use Cases for Each Method

- Packaging Appearance and Consumer Appeal

- Supply Chain and Logistics Considerations

- Conclusion: Why Vacuum Sealing Is a Smarter Choice for Most Businesses

What Is Vacuum Sealing? A Simple Explanation

Small businesses in the food packaging industry use vacuum sealer technology to protect their products through the extension of shelf life and delivery of safety levels. Vacuum sealing packages requires the removal of air oxygen followed by tight sealing of the container. Food preservation occurs through vacuum sealing because bacteria, along with mold and yeast, find it challenging to grow without oxygen, thus maintaining both freshness and texture and nutritional value. The packaging technique enables products to maintain freshness at a much superior level than conventional packaging solutions.

The best vacuum sealer machines today offer not only strong sealing capabilities but also user-friendly interfaces and consistent performance. Jiaolong stands among the leading vacuum sealer manufacturers who focus on manufacturing advanced, high-quality equipment for wholesale and commercial applications. Vacuum sealing technology from Jiaolong protects all types of food products while extending their shelf life, which makes it an optimal solution for businesses that need reliable and efficient food protection.

What Is Modified Atmosphere Packaging (MAP)?

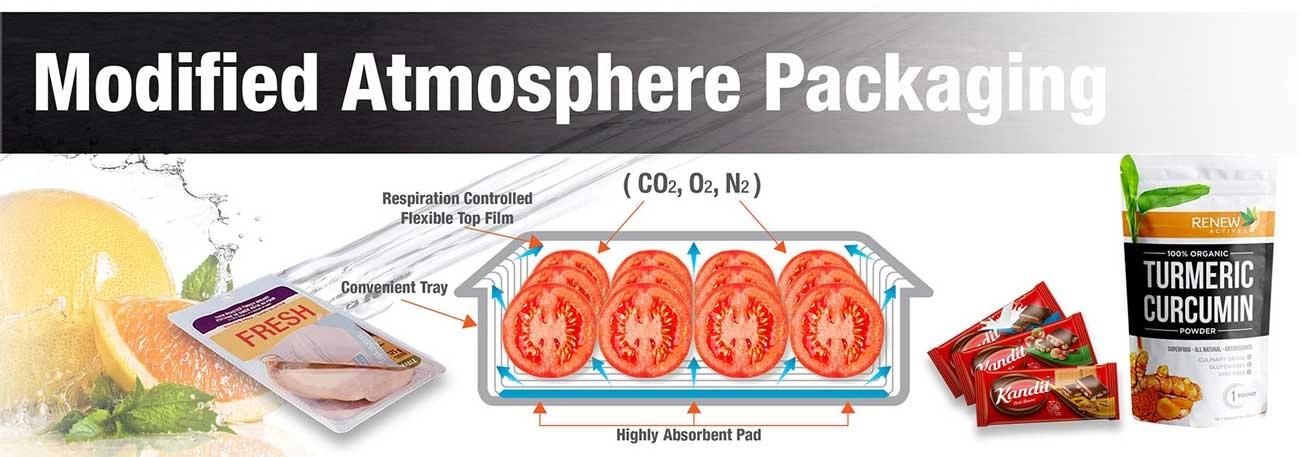

Modified Atmosphere Packaging (MAP) is another widely used method to prolong shelf life. The method operates differently than vacuum sealing. MAP technology replaces package air with a precisely measured blend of carbon dioxide, nitrogen, and oxygen gases to slow down spoilage reactions. MAP proves valuable for preserving foods that experience negative effects from pressure, such as leafy greens and bakery products.

The MAP technique provides effective preservation for specific food items but needs sophisticated machinery along with strict manufacturing conditions. Higher operational expenses might occur because businesses need specific gas mixes combined with continual monitoring systems. The choice of technology for small to medium enterprises and numerous businesses depends on balancing performance outcomes with operational expenses and system complexity, and here a vacuum sealer demonstrates superior value.

Key Differences Between Vacuum Sealing and Modified

Atmosphere Packaging

The selection between vacuum sealer technology and modified atmosphere packaging (MAP) proves difficult when one lacks thorough knowledge about operational differences between the methods. The preservation methods of vacuum sealer technology and modified atmosphere packaging differ extensively through their operational approaches, equipment requirements, cost implications, and targeted applications. Businesses need to examine these distinctions thoroughly before selecting their preferred method because their product needs and production requirements determine the best solution.

The following sections provide a breakdown of all aspects for each technology, starting from operational procedures to feasibility prices and delivery effects, so you can determine which solution best fits your business needs.

How Each Technology Works: Vacuum vs. Gas Flushing

Vacuum sealing eliminates nearly all package air while establishing an atmosphere with limited oxygen availability. A tight seal on the package blocks both oxidation reactions and microbial growth. Operation and maintenance of the vacuum sealer remain straightforward because it performs basic suction and heat-sealing mechanics.

The MAP process substitutes air with carefully selected gas combinations, which typically consist of CO₂, N₂, and O₂. The packaging requires gas flushing followed by sealing operations, which need gas cylinders along with regulators and sometimes continuous monitoring to achieve the correct gas composition. The application of MAP brings benefits to pressure-sensitive products, yet its complicated nature requires trained personnel with advanced technical expertise.

Shelf Life Extension: Which Method Performs Better?

The two methods extend product shelf life better than traditional packaging while showing different results depending on product type. The power of vacuum sealing reaches its peak when used to protect raw meat and seafood, as well as cheeses and cooked meals, from oxygen damage. The elimination of oxygen through vacuum sealing methods enables bacterial spoilage and enzymatic degradation to slow down, which results in shelf life extension of 3–5 times.

The modified atmosphere packaging technique works best for sensitive foods that include salads, berries, and baked goods, which could break when exposed to vacuum pressure. The shelf-life extension from MAP is shorter than vacuum sealing for perishable products because it either keeps a small amount of oxygen or requires specific gas mixes.

Cost Comparison: Equipment, Materials and Operational Expenses

Investment costs, together with operating expenses, become essential considerations during the selection process for packaging equipment. The cost of buying a vacuum sealer remains affordable because it uses standard vacuum bags together with occasional maintenance requirements. Operation of vacuum sealers does not require consumable gases, which results in predictable and low operational expenses.

The initial investment for MAP systems becomes higher because businesses need gas mixers together with analyzers and specialized packaging machines. The ongoing expenses of packaging equipment consist of gas supplies and cylinder rentals and maintenance requirements for additional components. The acquisition of a wholesale vacuum sealer from Jiaolong as a reputable manufacturer provides businesses with a cost-effective solution for operational efficiency.

Efficiency and Maintenance: Which Technology Is Easier to Manage?

Vacuum sealers earn high praise due to their long-lasting nature and their simple operation and easy upkeep requirements. Standard cleaning procedures combined with occasional replacement of seal bars maintain smooth operation for most vacuum sealer models, which need basic training to operate. Jiaolong stands among leading suppliers who deliver strong, user-friendly vacuum machines that reduce maintenance requirements.

The operation of MAP systems demands complex equipment setups since gas cylinders and regulators, along with analyzers, require constant calibration and monitoring. Product batches can become completely compromised when gas balance shows even minor issues, which results in lost products and added quality control responsibilities. Organizations that want a trouble-free and efficient solution prefer vacuum sealing over other methods because it offers easier management.

Food Compatibility: Best Use Cases for Each Method

The selection of appropriate packaging methods depends heavily on what type of product needs to be packaged. Vacuum sealing functions as the leading preservation method for dense, high-moisture foods, including meats, fish, poultry, cheese, soups, and stews. The packaging method effectively retains moisture while stopping freezer burn when storing food in cold conditions. Vacuum pressure causes deformation of delicate foods, which makes it unsuitable for packaging leafy greens and bakery goods.

The protective gas layer created by MAP technology offers protection to foods that break easily when compressed. The MAP packaging method works best for preserving the shape and texture of lettuce and strawberries, along with bread and similar products. Businesses operating with robust or semi-solid food products should choose a vacuum sealer because it offers better versatility and cost-effectiveness compared to MAP.

Packaging Appearance and Consumer Appeal

The appearance of products strongly determines how consumers react to them. Vacuum-sealed packages present themselves with a clean, polished, professional appearance. A tight product fit in packaging helps present freshness by eliminating wrinkles and revealing a clear and unclouded appearance that attracts customers at retail displays.

MAP packaging creates a puffy appearance because of the gas inclusion, which might mislead consumers about freshness levels in specific markets. The best vacuum sealer will deliver uniform packaging quality, which enhances brand image and earns customer trust.

Supply Chain and Logistics Considerations

Vacuum sealing demonstrates outstanding performance in terms of logistical efficiency. The vacuum sealing process makes products smaller in size, which leads to reduced warehouse and transport vehicle storage requirements. The packaging method offers compact storage capabilities because packages stack easily without package collapse risks.

The gas contained inside MAP packages makes them occupy more space than vacuum-sealed packages. Vacuum-sealed products take up less space during storage and transportation while requiring better handling methods because of their compact structure. Vacuum sealer technology provides businesses with the best storage density optimization and shipping cost reduction together with simplified inventory management.

Conclusion: Why Vacuum Sealing Is a Smarter Choice for Most Businesses

Vacuum sealer technology surpasses modified atmosphere packaging because it provides businesses with simple operation and lower costs and works with a wider range of foods. The vacuum sealing method delivers superior efficiency together with sustainability and ease of use, which benefits businesses that aim for high return on investment and simple operation.

Jiaolong stands as an example of how to evaluate new packaging equipment because it represents a trusted vacuum sealer manufacturer. Jiaolong stands out as a vacuum sealer manufacturer that delivers exceptional solutions for wholesale and commercial customers through its commitment to quality products and innovative designs and exceptional customer service.

Your food packaging business is ready to experience growth. Discover Jiaolong's premium solutions through their website to become a trusted partner with one of the leading vacuum sealer manufacturers in the market.

The Best Sous Vide Steak Machines (2026): Lab-Tested Reviews & Speed Comparisons

The 2026 Vacuum Sealer Market: Why High-Performance Motors are Driving B2B Growth

Slow Press Juicers in 2026: How Cold Extraction Redefines Nutrition, Yield, and Motor Engineering

Preserve Perfection: Discovering the Best Vacuum Sealer for Food Freshness in 2026

Mastering Mastication: Your Complete Guide to the 'Juicer Machine Slow' Revolution

Service

Is there a charge for installation service?

We provide free installation and commissioning services.

How should I perform regular maintenance of the equipment?

We provide regular maintenance services and can also provide you with specific maintenance suggestions and guidance.

What if there is a problem with the equipment during use?

You can contact our technical support team at any time through the contact information we provide, and we will solve the problem for you as soon as possible.

What if the device fails during the warranty period?

If your device fails during the warranty period, we will provide you with free repair services.

OEM & ODM

Can I conduct a small batch production trial?

Yes, we strongly support small batch production trials, especially in ODM services. You can conduct a small batch production first to verify the market demand and quality of the product before deciding whether to proceed with large-scale production.

Jiaolong's L601 Slow Juicer: The perfect choice for slow juicer manufacturers, suppliers, and wholesalers. High-quality, efficient extraction. Contact us for wholesale inquiries.

Jiaolong's L605A Slow Juicer: A high-quality slow juicer for OEM, manufacturing, and supply needs. Contact us today to explore our slow juicer manufacturing capabilities and become a valued partner.

Jiaolong's L606A slow juicer: The ultimate slow juicer for wholesale, manufactured and supplied by a leading slow juicer supplier. Experience superior juice extraction and quality. Contact us for bulk orders.

Jiaolong's Sous Vide SV220: A premium Sous Vide ODM solution. Reliable and efficient, the SV220 is the perfect choice for your next project. Partner with a leading sous vide supplier. Contact us today!

Contact Us for Customized Kitchen Appliance Solutions

Have any questions or cooperation needs? We are here to help you at any time!

Please contact us through the following methods, we look forward to working with you to create a better kitchen life experience!

© 2025 JIAOLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap